Exploring the World of Elevators: Typical Issues Dealt With by Numerous Lift Systems

As we navigate with the vertical transportation systems of modern structures, elevators stand apart as an important component of our lives. Nonetheless, behind their seamless operation exists a globe of elaborate mechanisms that can in some cases encounter challenges. From hydraulic elevators to grip systems and machine-room-less layouts, each lift type comes with its set of common issues. Recognizing these obstacles is essential for guaranteeing the smooth functioning of these vital systems. Allow's check out the complexities that underlie the operation of elevators and the potential issues that can develop, clarifying the intricate internet of lift devices.

Hydraulic Lifts

Hydraulic lifts, typically preferred for low-rise structures, use fluid stress to manage the activity of the lift cars and truck (lift repair companies). This mechanism involves a hydraulic pump pressing oil right into a cylinder, causing the lift to move in the desired instructions. While hydraulic lifts are understood for their smooth and peaceful procedure, they do come with their very own set of usual concerns

One prevalent trouble with hydraulic lifts is oil leakage. In addition, concerns with the control system, such as damaged shutoffs or a malfunctioning pump, can create disturbances in the lift's movement.

Regular maintenance and prompt repair services are vital to guarantee the smooth performance of hydraulic lifts. By addressing these typical concerns proactively, building proprietors can reduce downtime and make certain the security and performance of their upright transportation system.

Grip Lifts

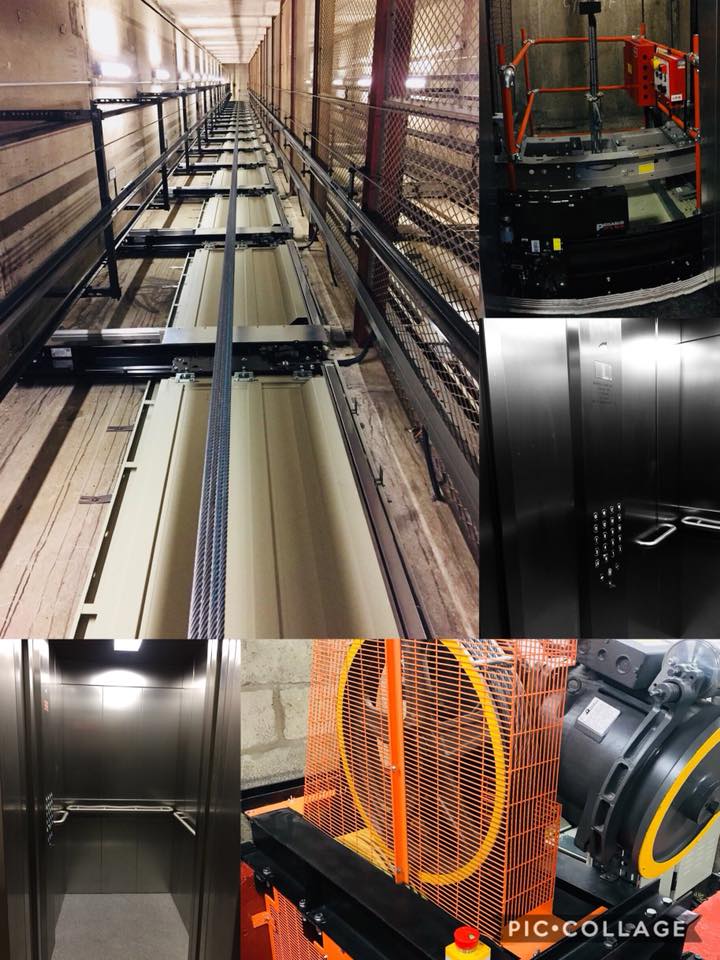

When thinking about vertical transport systems in buildings, an additional typical kind in addition to hydraulic elevators is the traction lift. Traction lifts operate utilizing a system of ropes and weights that relocate the lift automobile by gripping onto the hoist ropes. This system permits smoother and much faster vertical transportation compared to hydraulic systems.

Among the common problems dealt with by grip elevators is rope wear. The continuous movement of the ropes within the traction system can result in damage in time, potentially causing the lift to breakdown or end up being dangerous for usage. Normal examinations and upkeep of the ropes are important to make sure the elevator's proper performance and security.

An additional concern that grip lifts might run into is associated to the control system. Troubles with the control system can cause issues such as irregular movement, delays in response times, and even complete shutdowns. Normal screening and upkeep of the control system are essential to protect against such concerns and make certain the elevator's reliability.

Machine-Room-Less (MRL) Lifts

One of view the crucial parts of MRL lifts is the small gearless grip device that is installed within the hoistway. This equipment effectively drives the lift auto without the requirement for bulky devices found in conventional traction elevators. Additionally, MRL lifts generally use a counterweight system to balance the automobile, more improving their power effectiveness.

Despite their advantages, MRL elevators may encounter obstacles connected to maintenance and repair work due to the restricted space for equipment installment. Ease of access for servicing parts within the shaft can be restricted, needing specialized training for specialists. Proper maintenance routines and normal inspections are essential to make sure the his comment is here ongoing smooth procedure of MRL elevators.

Overloading and Weight Limit Issues

Overloading and weight restriction issues are critical worries in lift procedures. Lift suppliers design raises with certain weight capacities to ensure guest security and devices longevity.

When lifts are overwhelmed, it puts excessive pressure on the electric motor, cable televisions, and other parts, possibly triggering break downs or malfunctions. If they discover excess weight, safety mechanisms such as sensors and overload sensing units are in area to stop elevators from relocating. In addition, surpassing weight limitations can result in enhanced energy intake and damage on the lift system.

To alleviate overwhelming problems, building managers should plainly present weight restrictions in elevators and enlighten owners on the value of sticking to these constraints - lift repair companies. Regular upkeep checks by certified service technicians can additionally help make certain that lifts are running within safe weight specifications. By addressing overloading and weight limit concerns proactively, structure proprietors can boost elevator safety and security and efficiency

Electric System Failings

Surpassing weight restrictions in lifts can not only lead to mechanical issues however additionally potentially add to electrical system failures within the lift infrastructure. Electric system failings are an essential problem in elevator operation, as they can cause unforeseen shutdowns, breakdowns, or also security threats.

Furthermore, power rises or changes in the electric supply can likewise disrupt the elevator's procedure, impacting its performance and safety. These electrical disturbances can damage delicate elevator components such as control board, circuit boards, or sensors, resulting in system failings. Routine maintenance and examinations are essential to identify and resolve Visit Website possible electric problems quickly, making certain the effective and safe procedure of elevator systems. By sticking to weight restrictions and conducting routine electric system checks, building owners can minimize the danger of electrical failings in lifts.

Verdict

Hydraulic elevators, commonly chosen for low-rise structures, utilize fluid stress to regulate the motion of the elevator automobile.When considering vertical transport systems in structures, one more typical kind aside from hydraulic elevators is the grip elevator. Traction lifts operate using a system of ropes and counterweights that relocate the elevator cars and truck by grasping onto the hoist ropes. Unlike typical lifts that need a separate device room to house the equipment, MRL lifts incorporate many of the components within the shaft, eliminating the need for a dedicated equipment area.In verdict, elevators face common issues such as hydraulic malfunctions, traction system failings, and electric system problems.